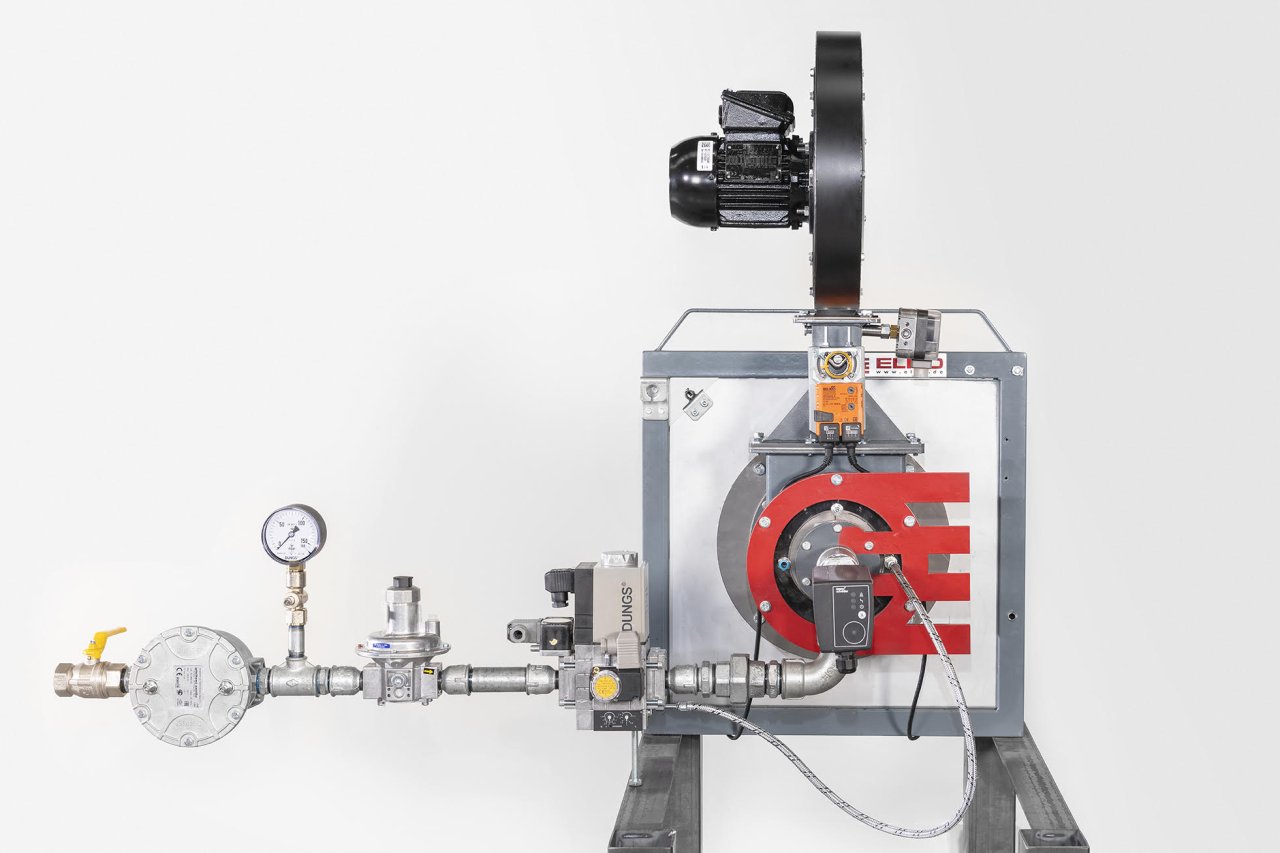

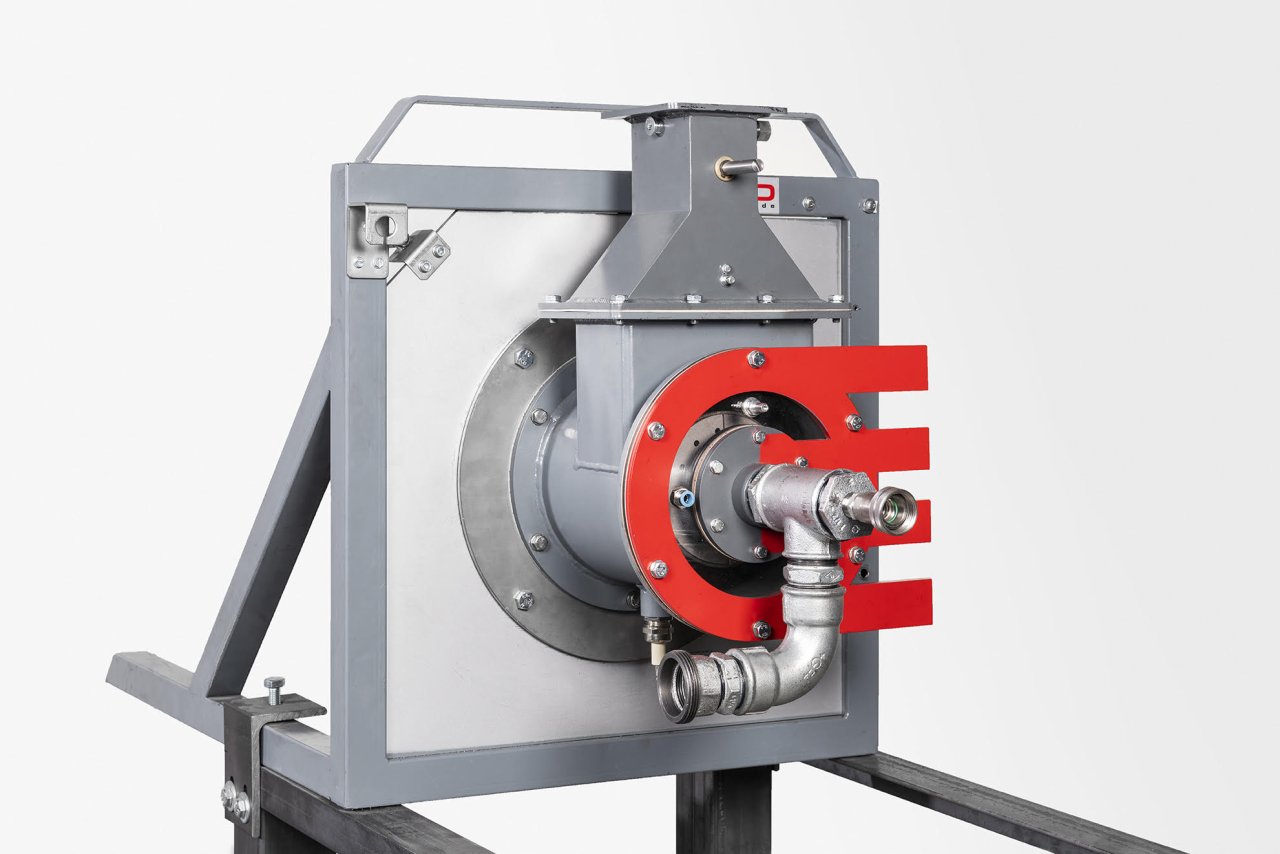

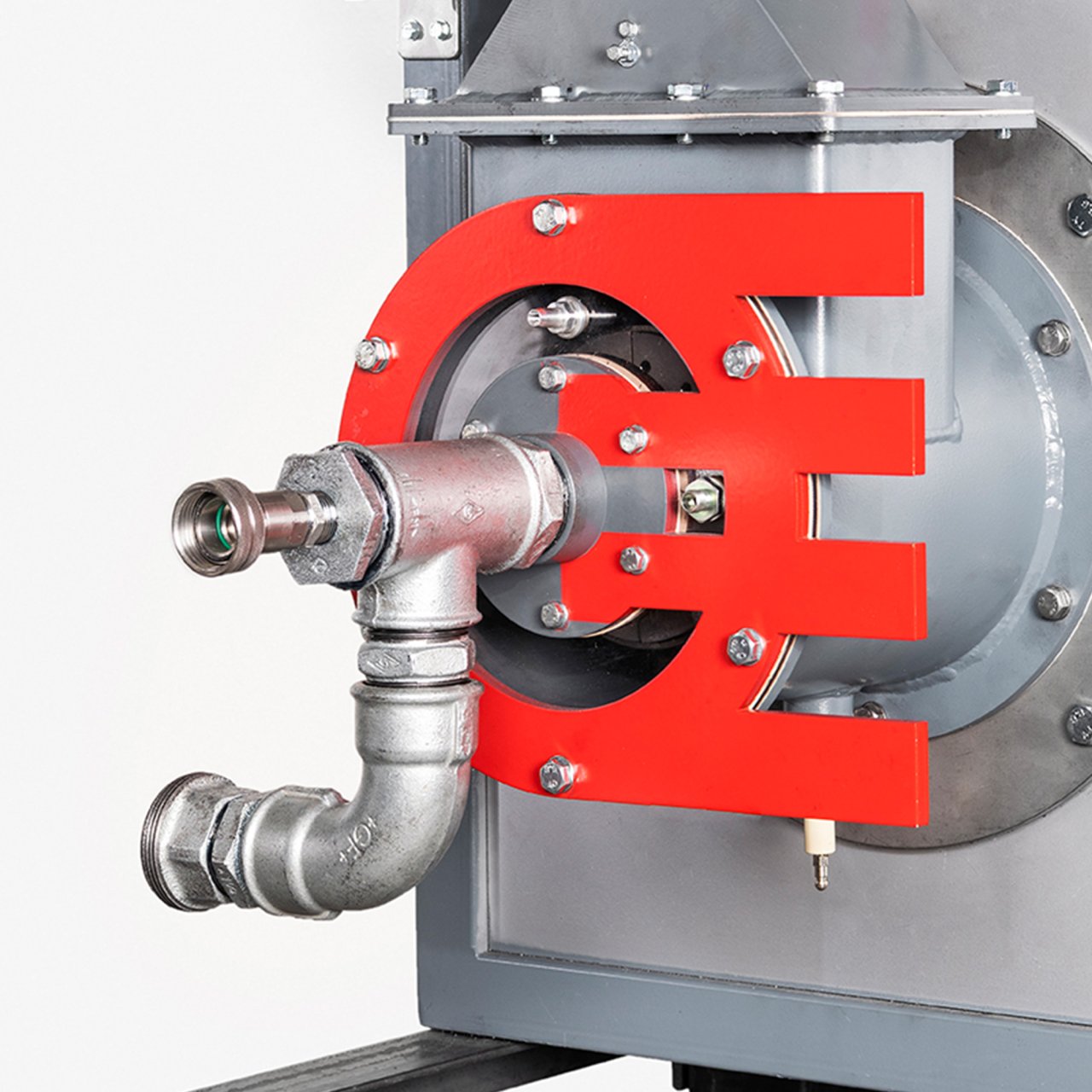

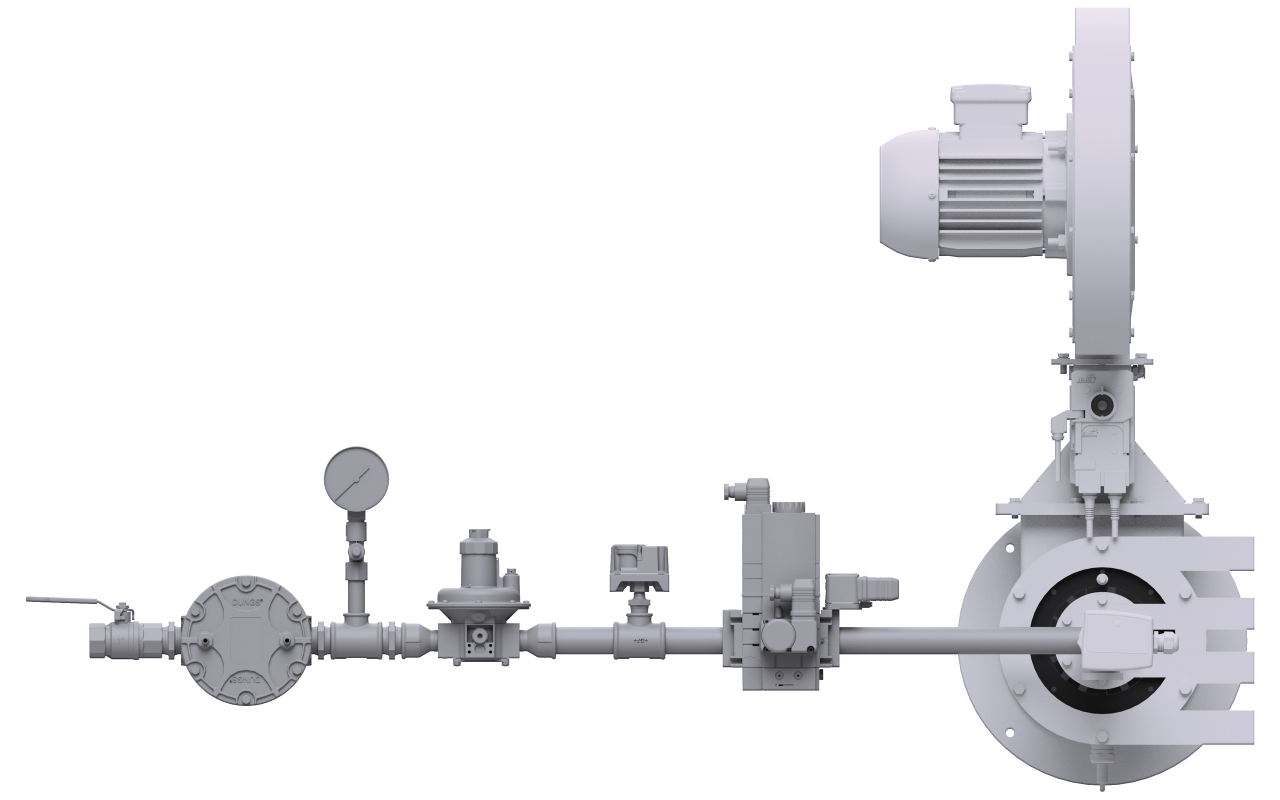

Areas of Application

Industrial thermal processing systems – directly and indirectly heated. Successfully used in systems for drying and heat treatment. Deployed in the industry for building materials and sealing and filter technology, as well as in foundries, in plastics and metal processing.